What is Hyperspectral Imaging?

Hyperspectral Imaging (HSI) is an advanced technology that combines machine vision and spectroscopy. Detailed information is captured about the spectrum of an object, offering a wide range of possible application across various industries. Let’s start from the beginning…

The Development of Imaging Technology

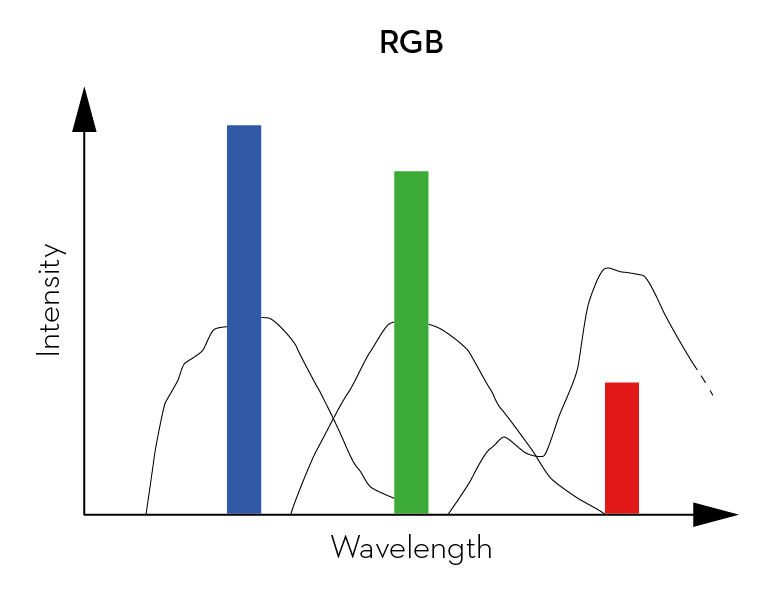

The development of imaging technology began with monochrome cameras capable of capturing only intensity information without colour information. Over time, RGB cameras were invented, which can distinguish three different spectral ranges in the visible region of the electromagnetic spectrum. These cameras mimic the spectral response of the human eye, providing better visual representation of the image for human observation.

Compared to monochrome cameras, RGB cameras provide significantly more information and are the natural choice for applications where human visual perception is relevant.

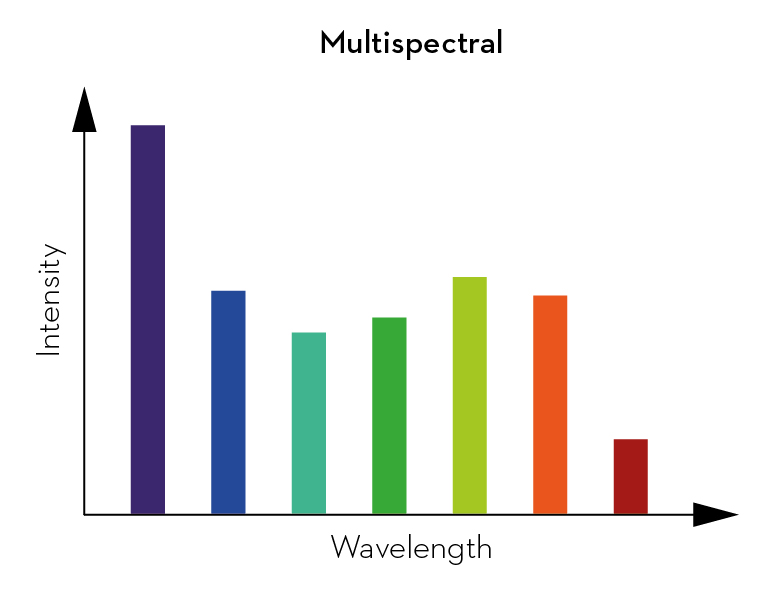

Multispectral cameras offer a larger number of spectral bands compared to RGB cameras, typically ranging from four to ten bands. These bands can be customized depending on the application and offer a cost-effective option for simple sorting applications. However, the bands in multispectral cameras are not usually directly adjacent or evenly distributed, making them unsuitable for spectroscopy.

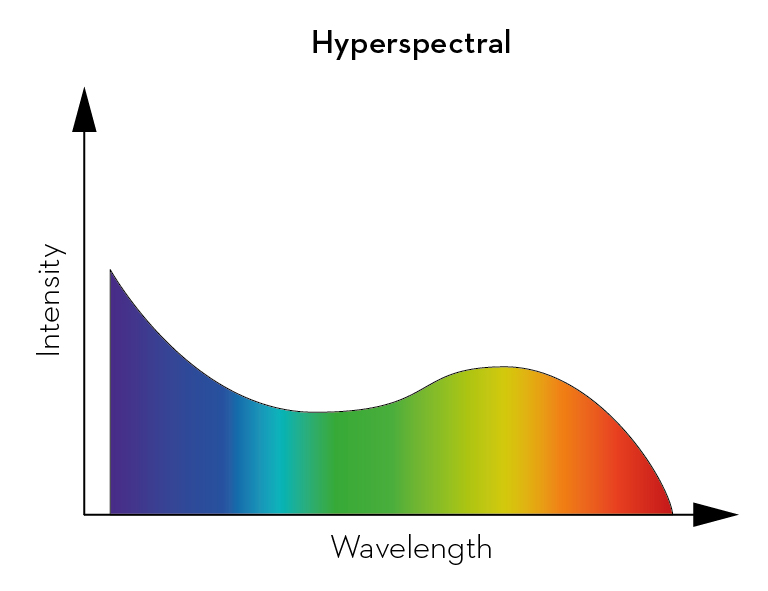

Hyperspectral cameras take the final step from being solely imaging cameras to actual spectrometers. They provide dozens to hundreds of spectral bands, usually directly adjacent and evenly distributed. This allows hyperspectral systems to apply established spectroscopic techniques such as derivative spectroscopy, chemometrics, and others. As a result, they become highly versatile tools for various applications in chemical detection, analytics, and sensor-based sorting.

Originally, hyperspectral imaging was developed for remote sensing applications in satellites and airborne measurement systems. As a pioneer for industrial applications, EVK introduced the first generation of the HELIOS hyperspectral camera for the recycling industry back in 2006. EVK HELIOS hyperspectral cameras measure in the near-infrared and short-wave infrared range from 930 nm to 1700 nm. which is particularly useful for material identification.

Both hyperspectral imaging and imaging spectroscopic systems provide spatially resolved spectroscopic information about a sample. Spectrally calibrated hyperspectral cameras have become the norm in the machine vision industry since their introduction by EVK. The distinction between a hyperspectral camera and an imaging spectrometer is no longer fundamental with the emphasis instead on specific performance metrics. Hyperspectral imaging is a powerful method for machine vision applications such as in-line measurements, monitoring, sensor-based sorting, quality control, foreign object detection and much more.

Hyperspectral Camera Features

The main optical features of a hyperspectral camera for machine vision applications include:

- Spectral range

- Frame rate

- Spatial resolution

- Spectral resolution (optical)

- Spatial sampling (number of pixels)

- Spectral sampling (number of spectral bins)

- Temporal sampling (framerate)

- Light efficiency

- Light responsivity

- Signal-to-noise ratio

- Dynamic range

Often a great deal of emphasis is placed on typical features such as spatial sampling (number of pixels) and frame rate, the responsivity and signal-to-noise ratio are often more important for proper data quality, especially in high-speed applications with short exposure time, where high illumination powers are needed.

Other important characteristics include how robust the technology is and whether it can handle the specific demands of industrial environments and cope with factors such as dust, vibrations, temperature, and moisture, their calibration stability, temperature stability, and ease of device replacement.

EVK hyperspectral cameras are industry-proven, robust devices without moving mechanical parts, optimized for industrial environments and 24/7 operation. The cameras deliver high-quality, calibrated spectral data at high speed, with high spectral resolution, very high light sensitivity and very good signal-to-noise ratio and dynamic range.

In addition, the real-time computing engines offer state-of-the-art spectral pre-processing (e.g. filtering, derivation, normalization) and integrated chemometrics to output a chemical image stream in real-time RGB false colour coding.

Types of Hyperspectral Cameras

Hyperspectral cameras come in different shapes and sizes, each with distinct features, advantages, and disadvantages. They are generally categorized according to function as follows:

Snapshot Hyperspectral Imagers

Snapshot hyperspectral imagers capture a multispectral two-dimensional image with a single shot. These cameras are typically designed similarly to an RGB sensor. Their advantage is their lightweight and compact design. They usually capture 16 to 64 different spectral bands. However, the actual spatial resolution suffers in this type of hyperspectral camera and is not optimal for chemometric applications due to the low number of measured spectral bands.

Whisk-Broom Hyperspectral Imagers

Whisk-broom hyperspectral imagers are single point spectrometers, which generate imaging information by scanning over a sample. As these systems rely on moving parts, they are susceptible to vibrations and are not maintenance-free.

Spectral Scanning Hyperspectral Imagers

Spectral scanning hyperspectral cameras are image sensors that sequentially measure different wavelengths, e.g. by filter wheels or variable filters. Their frame-rate will be reduced by the number of spectral bins recorded. Artifacts may occur when objects move and different wavelengths are captured at different times.

Push-Broom Hyperspectral Imagers

Push-broom hyperspectral cameras are line-scan cameras that project a straight line of image information through a dispersing system, typically an imaging spectrograph. One dimension of the sensor corresponds to the position on the scanned line, while the other represents the wavelength. This way, a spectrum is recorded directly for each point on the scanned line. Push-broom cameras are free from measurement errors caused by fast moving objects, making them ideal for continuous processes and continuous image streams. Push-broom imagers are the hyperspectral system predominantly used in sensor-based sorting, inline monitoring and analysis.

EVK HELIOS cameras are push-broom hyperpsectral cameras that enable high speeds and real-time measurements as well as chemometric evaluations of the data in real time. Thanks to these cameras it`s possible to make process decisions based on the chemical properties of fast-moving objects in real time.

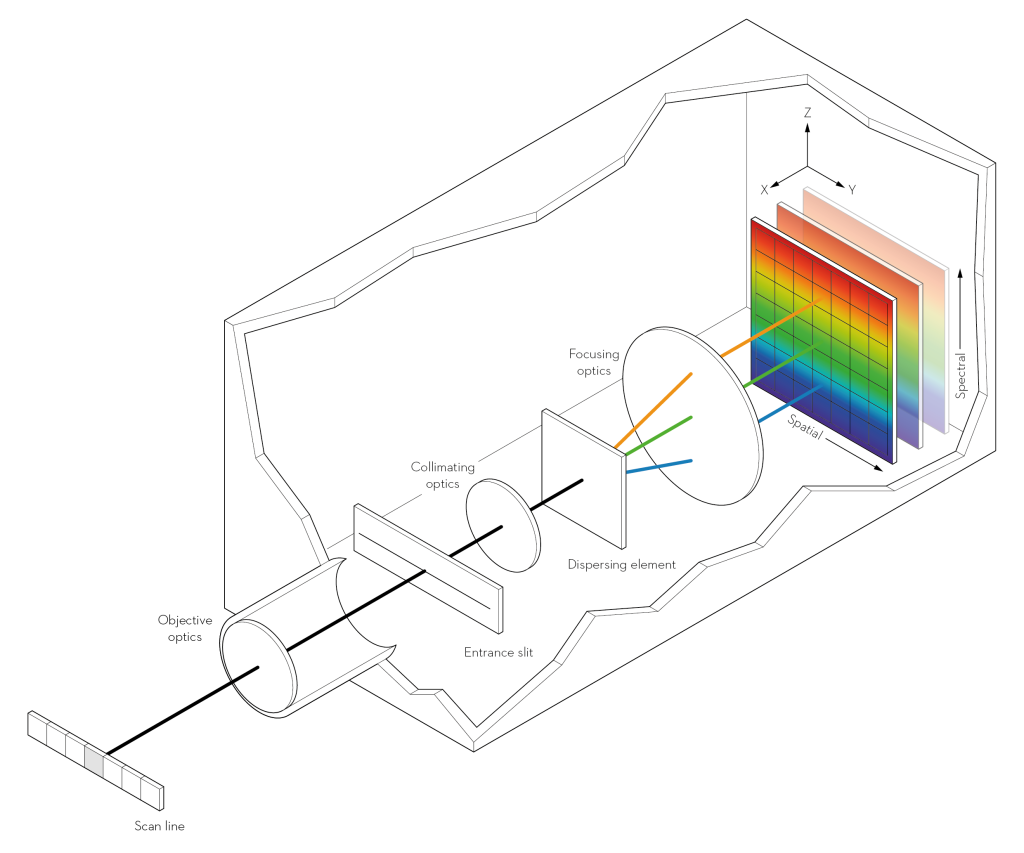

The Structure of a Push-Broom Hyperspectral Camera

A typical push-broom hyperspectral camera consists of an objective lens, an entrance slit, a collimator, a dispersive element, the focusing optics, and an imaging sensor. How these parts are arranged is shown in the following figure.

The scenery is projected by the objective lens onto the entrance slit. The collimation optics collimate the centerline of the scene, meaning that the light rays of each point in the scene are parallel to each other. The dispersive element separates the radiation into different angles for different wavelengths, while the focusing optics reconstruct the image on the sensor plane. This ensures all the information taken from the scanning line is on the sensor plane at all times. This means that when moving objects are recorded, motion blur happens at high exposure times but not to any reconstruction artifacts.

Hyperspectral Imaging - A brief summary

While the human eye perceives light only in three color bands (red, blue, green), hyperspectral cameras capture hundreds of spectral bands, making the invisible visible. This enables the precise classification of objects and parts of objects based on their chemical composition, which is visualized in false colors.

Hyperspectral line scan cameras capture the spectral signature of materials by analyzing the wavelengths of reflected light, creating a three-dimensional hyperspectral data cube. These cameras offer a non-invasive and non-destructive method for material classification, making them particularly valuable for automated quality control and demanding sorting applications.

You can find further articles about our technologies in the Technology Center

EVK Hyperspectral Imaging Systems

EVK HELIOS hyperspectral cameras

EVK HELIOS hyperspectral cameras are specially developed for industrial applications and work in real time and fully automated. They are available as a core camera (EC model) or with an integrated classification system (EQ model).

EVK ALPHA Real-Time Image Processing Platform

The EVK ALPHA is a powerful data processing platform for fast processing of spectral data. Combined with an EVK HELIOS EC hyperspectral camera, they are a powerful system for your industrial application.

EVK data analysis

The system is complemented by the EVK SQALAR software, which is used for the qualitative and quantitative analysis of chemical properties of individual objects, as well as for the simple creation of chemometric models.

EVK STREAM Supervisor monitors industrial material flows at multiple points and the key data obtained provides information about material distribution, belt occupancy, and material composition.

EVK Professional Services

Our EVK professional service team puts their extensive knowledge at your disposal right from the development phase and supports you throughout your project during conception, integration and commercialization.